Advantages

Excellent product quality and service

Competitive price,

“In-time” delivery

High tolerance

High tensile strength

Optimum performance

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment,machining and strictly final inspection prior to delivery

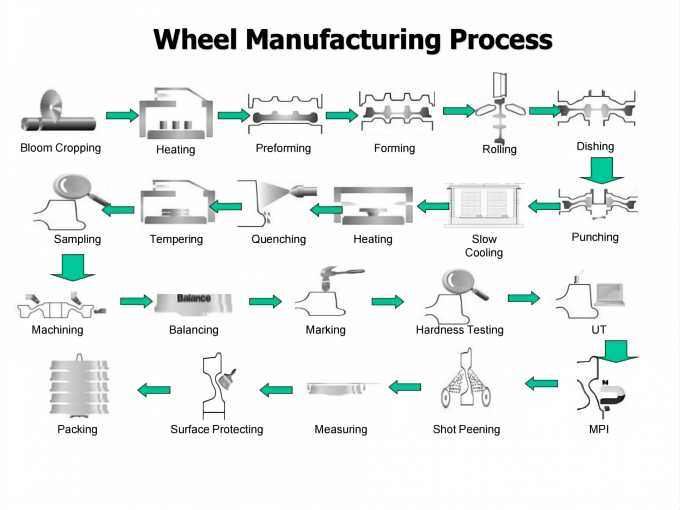

Manufacturing Process:

Billet Steel Review→ Cutting→ Heating→ Forging→ Heat Treatment→ Sampling Test→ Rough Machining→ Semi-Finish Machining→ Finish Machining→Hardness test→Static unbalance test → Ultrasonic Inspection→ Magnetic Particle Testing→ Packing

| The tests we conduct to ensure best quality |

| Chemical Analysis | Metallographic | Mechanical Analysis | Ultrasonic Testing |

| Magnetic Testing | Impact Testing | Hardness Testing | Surface Quality |

| Dimension Checks(CMM) | Customers' acceptance check or third party check |

To learn more about testing equipment and testing content, please read this article:What tests are performed on train wheels?